Description

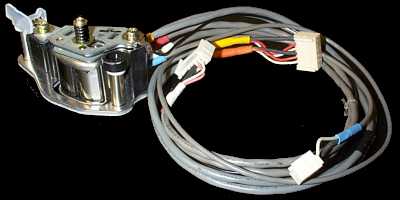

This is the ACE (Audio, Control, Erase) block used in the

SL-C9 /

SL-C20 /

SL-C24 /

SL-C30 /

SL-C40 /

SL-F25 /

SL-F30 /

SL-HF100 /

SL-HF150 /

SL-HF950. It reads the linear audio track from the video tape in a similar way to

a audio cassette player. Because the speed of the tape moving across the

head is slower than that of an audio cassette, the quality of sound reproduction

is not as good. Manufactures later solved this limitation by adding hi-fi sound heads

to the video head block. These rotate at a much higher speed and so allow for high

quality sound.

The control track is also read by the ACE head. This track is used

by the video servo circuits to sync up the video picture during playback.

Symptoms

Poor quality or low level audio:

The head often becomes worn with old age. When this

happens the sound quality suffers and the VCR can fail to operate. One

common symptom is that the real-time tape counter stops rotating. When this happens

it shows that the control track is not being read correctly. Under these fault

conditions, the picture can also start to roll.

Fixing

There a few things to try to improve the pick up on a worn ACE assembly (assuming that there are no faults with the circuit):

- Excessive head wear which creates a step/curve in the audio head pickup or dirt (which is more likely) on the face of the audio head.

Inspect the surface of the audio head and clean as necessary.

- The tape tension as regulated by the back-tension which is controlled by an arm sensing supply reel tape tension can reduce because the spring loses tension.

This reduces the tape contact with the head. It is possible to increase the tape tension by moving the spring mount position along the racket (sawtooth)

adjustment to the point at the extreme to the rear of the machine. This is observed through a hole in the metal reel base. On some models, back tension is

done electronically and so will need to be adjusted via a pot on the board.

- Tape path alignment. Again the tape contact to the head is reduced. This is usually only a problem if the tape was recorded on another machine.

- A new ACE assembly is the best solution (when still available) but at extremely

high prices which can often make the replacement prohibitively expensive.

Luckily, it is quite rare that the unit needs to be completely

replaced. It is usually sufficient to clean the head with alcohol and a lint

free cloth. There are also various adjustments which can be made. These inlclude

height, azimuth and tilt.

Adjustments on the head should only be performed with the use of an

oscilloscope and a test tape. In the case of the ACE above, tilt

adjustment is performed using the small grub screw on top of the unit

next to the screw with the spring. The aim of this adjustment is to

tilt the angle of the ACE so that it makes better contact with the

tape. The face of the ACE when new is flat but with age it wears into

a curved shape making this adjustment necessary.