Technical

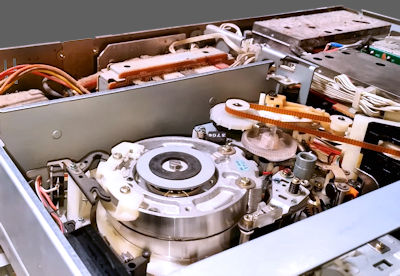

Inside view

|

Stops in play or recordThis is becoming a more common problem these days. The first thing to check is that there is adequate torque on the take up spool. If there isn't much then the cause is usually down to two contributing factors.

The first is the drive pendulum which can cease up and the second more

serious factor, is wear on the reel motor bottom bearing.

The pendulum is simple to replace but the bearing is moulded into

the chassis and replacement necessitates that the entire chassis be replaced.

One possible compromise is to fit a small piece of plastic into the bottom

bearing to raise the rotor and allow it to move freely. Sony supply

a repair kit for this purpose.

Stops in play, record and reverse/forward windDo not confuse this with the above symptoms. The problem in this case is due to lack of 4.43MHz colour sub-carrier reference in the servo circuit. This in turn is normally caused by failure of silicon fuse PS1 on the YC-25 board.Patterning on pictureIf you experience a patterning on the picture irrespective of whether you are viewing a tape or not then the most likely cause is that capacitor C319 in the power supply has dried up.No head drum rotationYou may find that the head drum fails to rotate. This is due to a problem with the Hall effect device on the head drum motor which is secured by a blob of glue. Full details on how to fix this can be found on the head motor page.Deck goes into rewindThis can be caused by failure of the tape end sensor. You can check this by unplugging the sensor at its socket on the PCB. |

|

|

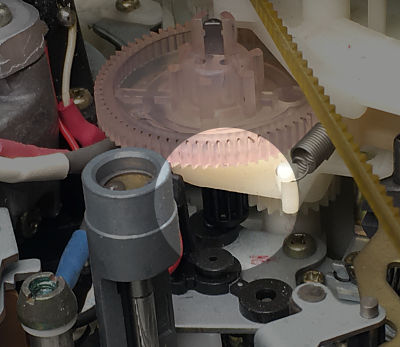

Loading gear and shaft repairThe loading shaft for the Sony has no official replacement but most times it can be repaired, unless the gear is in two pieces or a tooth has broken off. There are two approaches to solve this, either repair the broken gear, or purchase a similar gear and adapt it to fit.

In practice the diameter is sufficient and the reduced length does not really matter, just use super glue (or other suitable glue) to glue them to the shaft and protrude the shaft 1mm or so past the end.

See: RC-Toy-Car gears

If you don't need 50 then look for a smaller quantity but the price does not seem to change much. |

Quick fault guide

Please click on the button if you are able to contribute a solution to this list or would like to add to, or update PALsite's information on this model. Please note, questions will be removed.If you have a question about this model, please raise it on the chatpage.

| Fault | Solution |

|---|---|

| Damaging tapes or tape looping during eject | Check resistor R420 (3.3ohms) then transistor Q334 2SC10613 |

| Insufficient or excessive colour in playback | Check resistor R019 (56Kohms) on panel YC25. |

| Intermittently will not eject-cassette | Check connector CN608 on the SS16 panel for a poor contact. |

| No capstan servo lock in record | Suspect failure of transistor Q332 (2SC2458) on panel SS16. |

| No colour | Check the value of resistors R024 (56k ohms) & R278 (10k ohms) before suspecting capacitor C047, all on the YC25 panel. |

| No E-E picture after 15 seconds, records in black and white | Adjust RV009 for 4.3volts p-p at C104 on panel YC25. |

| No functions or display | Check 1C001 on the TP37 board |

| No play, FF or cue | Suspect failure of the forward sensor. |

| No take up / chewing tapes | Check condition & positioning of the pinch roller. |

| Not erasing previous recordings | Check for failure of Q503, Q501 then Q502 |

| On/standby switch inoperative and corrupt display | Check diode D001 on the TM37 panel. |

| Program display showing -au- | Check resistors R063 (120Kohms) & R073 (4.7ohms) before suspecting failure of IC003 on panel TU39 |

| Stopping in rewind / review mode | Suspect failure of transistor 0606 (2SC2458) on panel SS16 |

| Switches off shortly after switch on | Check PSU. In particular regulator IC401 (STR1229]) on the PS23 panel |

| Will not eject cassettes, pinch solenoid not operating | Check resistor R654 on panel S516 |

| Will not tune | Check for failure of IC004 on the TU39 board before suspecting the pre-set unit PS001 of failure |

| Intermittent squiggly patterning | Pattern is very similar to that caused by C319, but NOT applying to E-E loopthrough. Check Delay Line DL001 on video PCB. |

| tape not returning to cassette prior to eject | this is sometimes caused by the gears not fully engaging. press rewind stop then eject. |

| The machine only laces up half way | Check and clean Microswitch or replace if necessary. |

| Will not load / lace or eject tapes | When attempting to load a tape, the loading motor is seen to stall. This is due a fault in the loading / threading clutch assembly. (Located directly atop the loading motor). The clutch would jammed due to a cracked "sun" gear (the central gear in the clutch0. Replacing the gear cleared the fault. |